Fatigue crack initiation

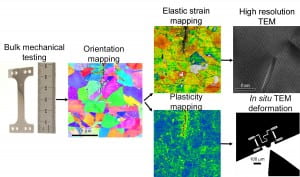

If you take 10 nominally identical samples and load each under fatigue until it fails, you’ll find that each sample can withstand a very different number of cycles, spanning orders of magnitude. This is due to tiny microstructural variations in the samples which can have a large influence on where and when cracks nucleate. We are using multiscale electron microscopy techniques, including EBSD analysis, in situ SEM and TEM deformation, and site specific analysis via FIB lift outs, to uncover the physics governing crack nucleation and growth under fatigue loading.

This work is supported by DOE BES

Material behavior in corrosive and embrittling environments

Materials used in application will almost always experience some form of corrosive influence, whether it be liquid metal coolants used in the next generation of nuclear reactors or simply the humidity in the air. We are developing in situ microscopy techniques to understand the relationship between microstructural features such as grain boundaries and dislocation configurations and the susceptibility to corrosive environments. Currently, we are investigating naval-relevant systems such as Al 5xxx in marine environments as well as model systems such as iron in acetic acid.

This work is supported by the Office of Naval Research

Strain localization and ductile fracture in Al alloys

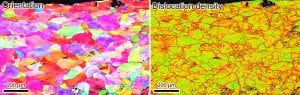

When subjected to mechanical stimuli, materials store the energy in the form of strain. Critical failure occurs when the damage accumulating within the material surpasses a critical value. Because alloys have complex microstructures, how they deform varies depending on where you look. In order to characterize this heterogeneous strain behavior, we perform in situ SEM tensile tests and measure plastic strain by tracking the movements of submicron precipitates on the alloy’s surface. The result shows where plastic strain localizes, indicated by red areas. Combining these techniques with EBSD data, we look for combinations of microstructural features that result in high strain response to understand the fundamental mechanics behind fracture of ductile alloys.