Associate Professor

Email: josh.kacher@mse.gatech.edu

Tel: 404-894-2781

Office: Love Building, Rm 282

Awards:

2021 NSF CAREER Award

2018 Bradley Stoughton Award for Young Teachers (ASM)

2017 DOE Early Career Research Award

2017 Office of Naval Research Young Investigator Award

2017 Class of 1969 Teaching Fellowship

2016 TMS Young Professional Development Award

Post Docs

Yang Su

Yang Su

Yang Su’s research focuses on the study of stress, strain and GND density in grain boundary vicinity in deformed FCC polycrystalline metals. Using in-situ cross correlation EBSD (HR-EBSD), one can capture the stress/strain caused by dislocation pile-ups and how local stress/strain tensor and GND density evolve with increasing global strain. By collecting HR-EBSD near a large number of grain boundaries (and twin boundaries), we hope to establish a correlation between the character of grain boundaries (or twin boundaries) and the maximum stress/strain that can be reached near those boundaries.

Graduate Researchers

Alex Butler

Alex’s research focuses on analyzing additively manufactured aluminum alloys using electron microscopy techniques such as SEM, EBSD, and TEM. Through the addition of ceramic inoculants, one can create an alloy with increased strength, but this sacrifices its ductility. Therefore, it is important to study how the microstructure evolves under deformation in order to understand how we can use and improve these materials especially for applications in aerospace.

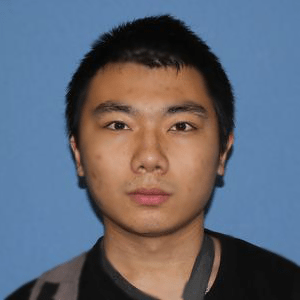

Yichen Yang

Yichen Yang

Yichen’s research focuses on the analysis of grain boundary migration as well as the effects of irradiation of UFG and NC pure metals. I conduct this research through observing the microstructure evolution from plastic deformation during in situ TEM deformation measurements using MEMS devices. The purpose is to understand the fundamental mechanisms governing the kinetics of plastic flow at the nanoscale. Characterization techniques such as SEM, TEM, and EBSD are utilized for quantifying dislocation dynamics.

Samrin Saiyara

Samrin Saiyara

Samrin’s research focuses on scaling up green steel production by understanding the thermodynamics of reduction reactions in various types of steel compositions. It also includes finding less hazardous solvents, optimizing furnace schedules, and controlling carbon and other chemical species in the production process.

.

.

.

Justin Nakamura

Justin Nakamura

Justin’s research focus is on Au-Al corrosion behavior specifically looking at the behavior of corrosion near intermetallics that form during wire bonding and a new project looking at hydrogen generation using nano-galvanic Al for hydrogen generation.

Alec Balandin

Alec Balandin

Alec’s research focuses on the extrusion kinetics and rheology involved in the green steel project. In the green steel project, net-shaped parts are formed by extruding oxide slurries, with the oxides comprising the targeted steel composition. This extruded material is then reduced and sintered in a hydrogen rich environment, resulting in a steel part. This study involves the use of mathematical modeling as well as electron microscopy characterization to achieve precise geometry on extruded materials.

.

Neyton Baltodano

Neyton’s research focuses on increasing the density of Molybdenum parts produced by the reduction of extruded molybdenum oxide pastes. He is working on investigating the kinetics of sintering as well as the reduction reaction that is performed on the molybdenum oxide paste after it is extruded from a die. Some of the production process parameters he will be examining closely are the furnace schedules, furnace atmosphere composition, and the addition of other elements to act as sintering aids.

.

Adam Jaafar

Adam Jaafar

Adam’s research focuses on high temperature in-situ TEM nanomechanics, specifically using a MEMS thermal nanotensile tester on 1-D nanostructures in tensile mode. He also uses SEM imaging to characterize morphology and topography to capture behaviors during creep tests. His research will improve the characterization of materials used in nuclear reactors which experience high temperatures and radiation doses. This is done with high-temperature, radiation-resistant materials such as silicon carbide (SiC) that can simulate the reactor conditions. FEA is used to simulate temperature profiles and thermal actuator beam deflection compared with those from experiments using different material properties and environmental conditions.

.

Masters Students

Qasem Alhassan

Undergraduate Researchers

Apurva Nayak

Ella Parker

Nathaniel Levander

Blake Moore

Jason He

Group Alumni

Graduate Students

Taylor Sloop (PhD 2024)

Lina Daza (MS 2024) – L3Harris

Sandra Stangebye (PhD 2023) – Raytheon

Enrique Quiros (MS 2023) – Intel

Sarah Lombardo (PhD 2022) – TEL

Katie Koube (PhD 2022) – ICON

Jahnavi Desai (PhD 2022)- KLA

Colin Stiers (MS 2022) – US Army

Yung Suk Jeremy Yoo (PhD 2020) – Intel

Jordan Key (PhD 2020) – Department of Defense

Undergraduate Students

Yuta Namekawa (2024)

Eli Winterscheidt (2024)

Shreya Paliwal (2024)

Jack Edge (2024)

Marc Boyer (2023)

Stefan Debates (2021)

Joseph Stover (2021)

Josephine Deronja (2021)

Devon Phelps (2021)

Lauren Holm (2021)

Christian Schneider (2021)

Frank Yu (2021)

Bishop Wright (2021)

Colin Stiers (2021)

Annie Mullins (2020)

Melissa Hernandez Guzman (2020)

Rishab Jain (2020)

Alex Yang (2020)

Michael Knudson (2020)

Xueqiao Wang (2019)

Sarah Blust (2019)

Cassiopeia “Cassi” Cartwright (2019)

Lovelyn Wirian (2019)

Amy Clark (2018)

Chase Scott (2017)

Victoria Ohmer (2017)